Hidden risks at work:

Carcinogenic chemicals need to be higher on the HSE agenda

Cancer is the most common cause of work-related death, accounting for more than half of all occupational deaths in Western countries. It is largely due to exposure to chemicals at work.

This clear message from the Norwegian National Institute of Occupational Health (STAMI) is a serious reminder of the need for better control and knowledge in working life.

Having up-to-date, documented and accessible information about carcinogenic chemicals in the workplace is crucial – both to protect workers here and now, and to ensure verifiable knowledge in the years to come. Many cancers develop over a long period of time, and exposures today can lead to serious illness decades later. Therefore, exposures must be logged and preserved, even when protective equipment is in use and the health effects are not immediately visible.

With a clear overview of which substances, processes and work operations involve risk, the company can work more purposefully with prevention, substitution and technical measures.

The costs of work-related cancer are high, both for individuals and society. For those affected, the disease can mean loss of health, ability to work and quality of life. It also affects relatives, who often find themselves in a demanding and unpredictable care situation. For society, this entails large expenses for treatment, social security benefits, lost labor and compensation cases. A systematic focus on documenting and registering chemical exposures is therefore not only good HSE – it is also socio-economically and ethically responsible.

Why do we need to prioritise carcinogenic chemicals?

According to STAMI, work-related cancer can be prevented – but only if we know who is exposed, to what, and in what quantities. In the article With good knowledge we can prevent work-related cancer, this is highlighted as a critical point: The most important sources of exposure are chemicals and dust in the process industry, construction, offshore activities and laboratories. Yet many companies lack the necessary overview and documentation.

This is also supported by the government’s national cancer strategy (2025-2035), where Ten-year goal 5: Prevent more, detect earlier states that work-related cancer should be reduced. The strategy points to the need for better registration, systematics and prevention, with particular emphasis on measures such as exposure registers and chemical inventory.

Prioritising the work with carcinogenic substances is therefore not just about regulatory compliance – it’s about protecting life and health through knowledge-based and documented HSE work.

Control of hazardous chemicals and exposures is crucial

Working with carcinogens occurs both through the use of classified chemicals, such as benzene, formaldehyde and gasoline, and in work processes that generate hazardous pollutants. Many of these process-generated substances are both widespread and underreported, posing a real health risk in a number of industries.

Examples of such sources of exposure include:

- Respirable crystalline silica (quartz): Particularly in drilling, concrete sawing, sandblasting and other work with mineral materials

- Asbestos: Which is still present in older buildings and poses a hazard during refurbishment and demolition

- Diesel exhaust: From vehicles and machinery in enclosed or poorly ventilated areas

- Welding fume: A complex mixture of metal oxides, nitrogen oxides and particles

- Radon: An invisible, radioactive gas that can build up in tunnels, basements and mining areas

In order to reduce health risks, and at the same time comply with the requirements of Chapter 31 of the Regulations on the Performance of Work, companies must have a systematic overview and documentation.

This means:

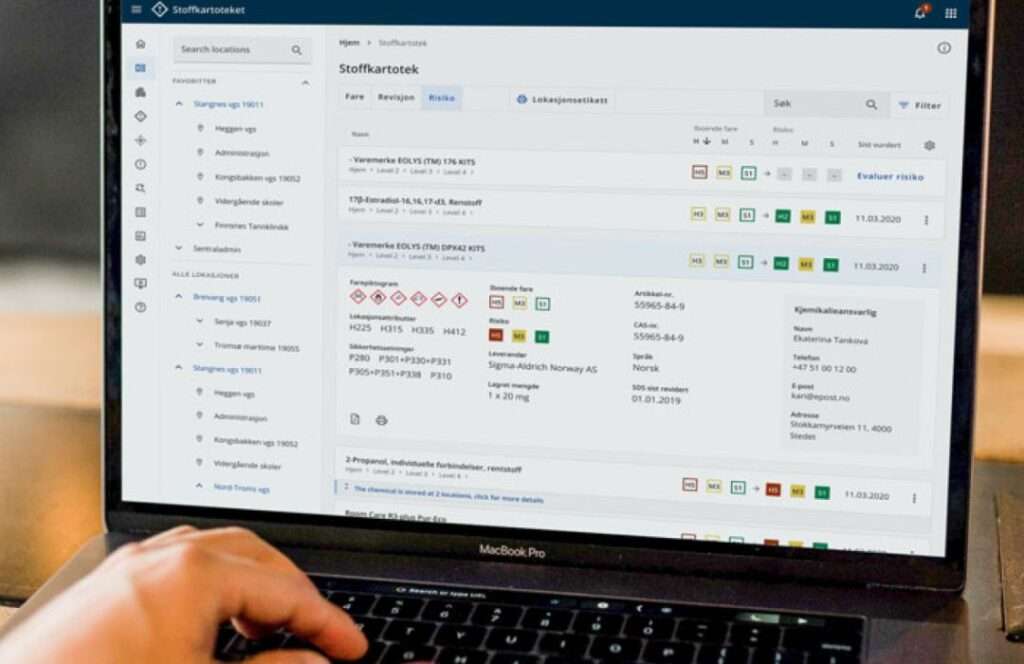

- Chemical inventory: Up-to-date overview of all hazardous chemicals in use and process-generated substances, including hazard labeling and safety data sheets

- Risk assessments: Mapping of which work operations and substances pose cancer risks, as well as which technical and organisational measures are required

- Exposure register: Accurate documentation of who has been exposed, to which substances, where and when – as a basis for health monitoring and possible compensation for occupational diseases

Exposure register – the most important document you (might) not have

An exposure register must be kept for employees who are, or may be, exposed to health hazards at work. This is a requirement in Chapter 31 of the Regulations on the performance of work, and applies to a number of known risk factors.

Who should be registered?

The exposure register includes employees who are or may be exposed:

1. Classified chemicals:

- Carcinogenic substances: Carc 1A / 1B

- Substances harmful to genetic material: Mut 1A / 1B

- Substances harmful to reproduction: Repr 1A / 1B

2. Specific processes and substances mentioned in the regulation:

- Preparation of auramine

- Exposure to polycyclic aromatic hydrocarbons (PAHs) in soot, tar or pitch

- Exposure to polycyclic aromatic hydrocarbons (PAHs) in soot, tar or pitch

- Preparation of 2-propanol by strongly acidic process

- Exposure to hardwood dust

3. Other exposures harmful to health:

- Lead and lead compounds

- Asbestos fiber and asbestos-containing dust

- Biological factors in infection risk group 3 or 4, or with annotation D

- Ionizing radiation

- Hazardous substances in rock work

Why is the exposure register so important?

The exposure register has three key purposes:

- To give the employer an overview of who has been exposed to harmful conditions

- Ensuring traceability over time, so that exposure can be traced even many decades later

- To be able to document exposure in cases concerning occupational diseases and claims for compensation, in accordance with the regulations on occupational diseases (section 1)

Requirements for duration and data quality

The register must be verifiable and stored for 40-60 years, which places high demands on data security, maintenance and system management. It is also important to note that the use of protective equipment does not exempt from registration – it is the exposure itself that must be documented, regardless of the level of protection.

A well-maintained exposure register is not only a legal requirement, but a key tool for long-term health monitoring, prevention and responsible working environment management.

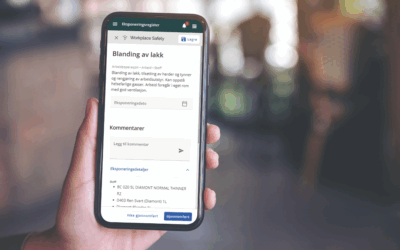

Digital tools that provide overview and control of chemicals

With good digital solutions in place, HSE work becomes more efficient, more verifiable and, not least, far better equipped to prevent health risks in practice. When it comes to chemical handling, this is particularly important: It must be possible to track, risk assess and follow up each individual chemical, over time and across workplaces.

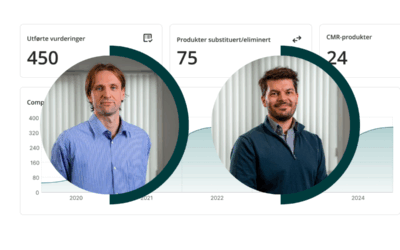

Digital tools such as Workplace Safety and ChemCenter have been developed precisely to meet these requirements. They support the company in working in a structured way with substance records, risk assessments and exposure overviews, and help ensure that chemical information is up-to-date, accessible and in line with regulations. The result is better control, higher quality documentation and better conditions for preventing damage to health. Such tools lay the foundation for HSE work that is effective, verifiable and sustainable over time.

Written by Hans Kristian Brekken, chemist and product developer at Workplace Safety.

Do you want guidance?

Many employers are unsure of what an exposure register should actually contain, how it should be established and what requirements apply in practice. Contact us for guidance on how to establish an exposure register with good routines that give you control, overview and peace of mind.