What is a chemical inventory?

A chemical inventory is first and foremost about order and overview, and is an important tool in the health, safety and environment (HSE) work of any company that handles hazardous chemicals. There are clear requirements for documentation and available information, and a chemical inventory collects this in one place so that laws, regulations and internal procedures are followed.

What is a chemical inventory?

A chemical is considered hazardous if it is classified in accordance with European legislation (REACH and CLP), either for health, physical or environmental hazards. A substance register is a collection of necessary information about hazardous chemicals in the workplace, including safety data sheets (SDS).

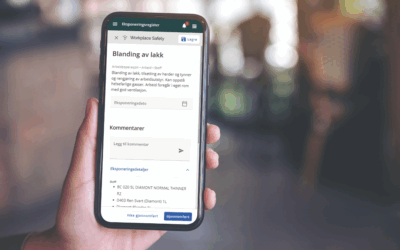

The purpose of a chemical inventory is to make it easy for employees to find relevant information for safe and efficient handling of chemicals. The safety data sheets provide guidance on both preventive measures – such as the use of protective equipment, correct storage and handling routines – and reactive measures in the event of accidents, such as spills, fires or exposure to chemicals. In this way, the chemical inventory serves as a practical tool both in day-to-day HSE work and in emergency situations.

What should a chemical inventory contain?

A chemical inventory must meet the requirements of the Norwegian Labor Inspection Authority’s guidelines, the European REACH regulations and the CLP regulations. In Norway, it is a requirement that the information in the chemical inventory must be in Norwegian. If employees are not fluent in Norwegian, the employer must ensure that the chemical information is made available in a language the employees understand.

As a minimum, the chemical inventory must contain:

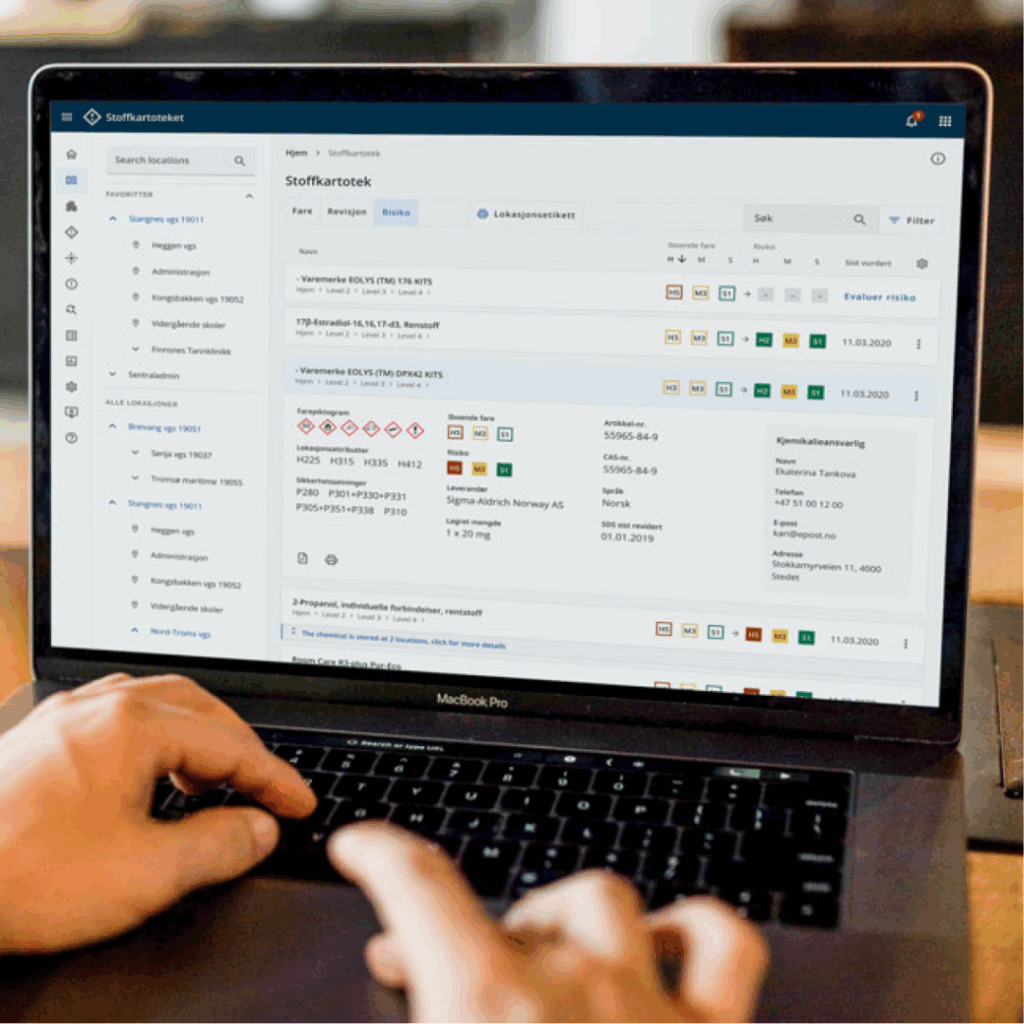

- Chemical overview with names, classification, hazard symbols and updated SDS for hazardous chemicals

- Information sheets for non-classified chemicals in the workplace, such as pharmaceuticals, welding fumes and other process-generated chemicals

- Risk assessments of the chemicals with preventive measures

Who is responsible?

Both the employer and the employee have certain responsibilities, but it is the employer who is primarily responsible for creating and maintaining the chemical inventory.

The employee’s responsibility:

- Follow established routines and procedures when handling hazardous chemicals

- Participate in necessary training in the use of the chemical inventory

- Report if information in the chemical inventory is missing or outdated

The employer’s responsibility:

- Creating and maintaining the chemical inventory

- Ensure that the chemical inventory is updated with valid SDS

- Ensure that the chemical inventory is in accordance with legal requirements

- Make the chemical inventory easily accessible (digitally or physically) for employees

- Provide necessary training in the use of the chemical inventory

Known challenges

Lack of quality control of SDS

For many companies, keeping their chemical inventory up to date is a challenge. Data sheets or chemical overviews may be out of date, resulting in incorrect or incomplete information. This weakens HSE work and can lead to both orders and fines from the authorities.

Difficult to find information

In the past, it was a requirement that the chemical inventory should be on paper. Many companies still use physical binders, which results in a lot of manual work. Regardless of the format, the MSDS can contain large amounts of information that can be difficult to navigate without good routines and adequate training.

How to get started with a chemical inventory

An effective chemical inventory starts with clear procedures for purchasing and systematic HSE work, as described in the company’s management system. Ensure that roles and responsibilities are clearly defined so that the chemical management system is followed up and maintained.

- Map the chemicals: Get an overview of all chemicals present in the workplace

- Build structure: Organise your chemical inventory to reflect how and where chemicals are stored

- Enter information: Register the chemicals and retrieve approved safety data sheets, preferably through an easy-to-use chemical management system

- Make the information accessible: Make sure that all employees who handle chemicals have easy access to the chemical inventory

- Keep your index up to date: Add new chemicals when purchasing, and archive products you no longer use

An up-to-date chemical inventory gives your business control over the chemicals it uses and is a legal requirement to prevent damage to health and the environment. With a digital and automated chemical system, it is easier to ensure that the information is always up-to-date, correct and accessible.