What is a safety data sheet for chemicals?

What is a safety data sheet for chemicals?

Did you know that all hazardous chemicals must have a safety data sheet? A safety data sheet can be the difference between control and chaos if an accident occurs. Find out what a safety data sheet is, why it is so important, and common challenges for businesses.

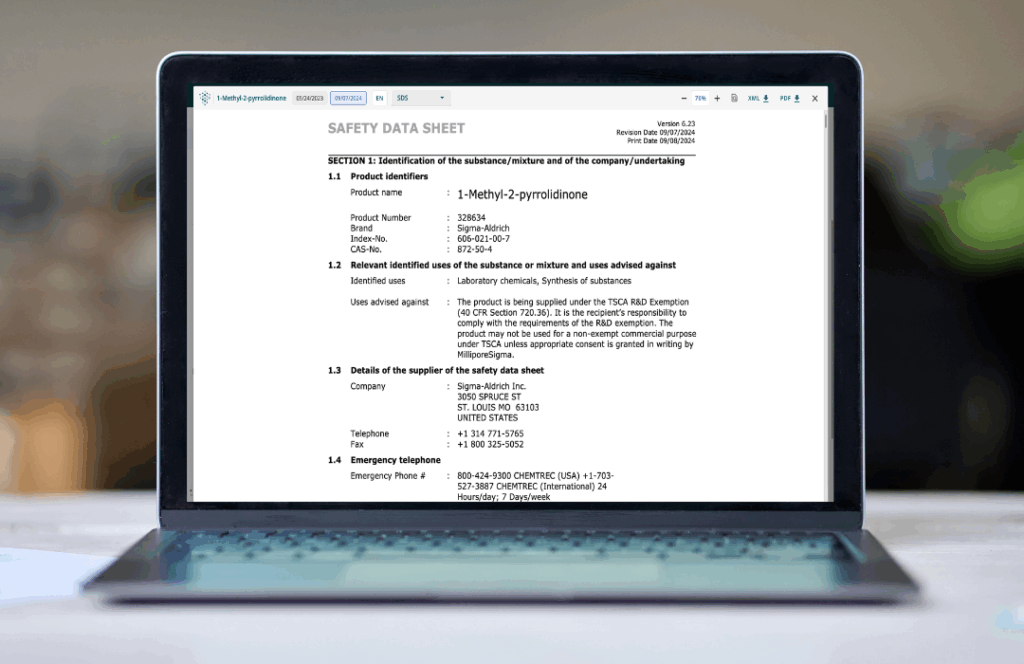

What is a safety data sheet (SDS)?

A Safety Data Sheet (SDS) is a document (digital or hard copy) that provides an overview of how chemicals should be handled, used and stored. All SDSs follow a standard 16-point layout so that the information is easy to find, no matter what chemical you are working with.

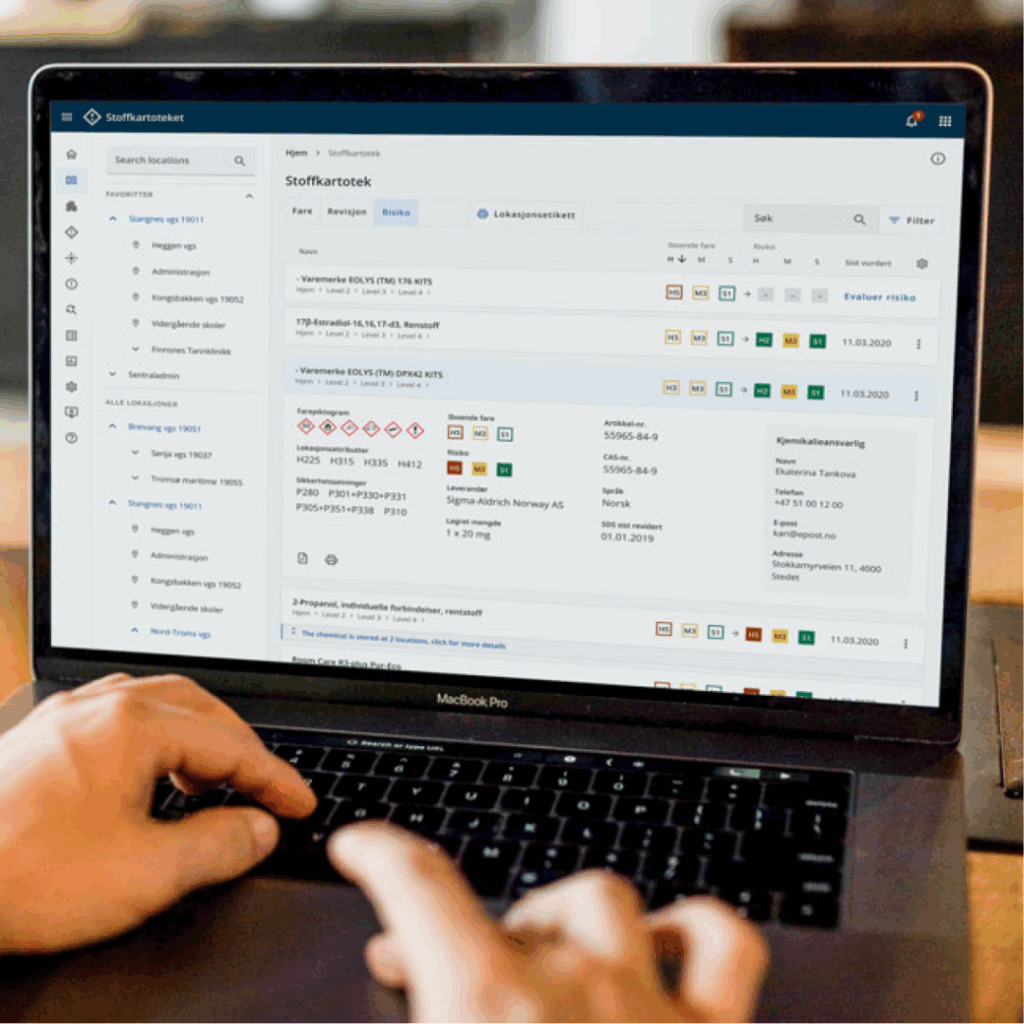

What is the difference between a safety data sheet and a chemical inventory?

A safety data sheet (SDS) provides information about a specific chemical, while a substance register provides an overview of all the chemicals in the company, and thus consists of several SDSs.

Why do we need safety data sheets?

SDSs are needed to handle chemicals safely, protect employees from health hazards and describe procedures for first aid, fire and spills. Not only that, but updated SDSs are required by law through the Regulations for the Performance of Work, REACH and CLP, and are an important part of a company’s health, safety and environment (HSE) work.

Examples of situations where SDS is needed:

- When receiving new chemicals in the workplace

- In the event of a spill, fire or other accident

- By supervision from the authorities

- During transport of dangerous goods

- When using a new chemical

- When disposing of waste

- In risk assessments

What should a data sheet contain?

A safety data sheet is always structured according to a fixed 16-point template. This makes it easy to find the right information, no matter what chemical you are working with.

The 16 points consist of:

- Identification (name of the substance/product and supplier)

- Hazard identification (health, fire and environmental hazards)

- Composition (content and hazardous components)

- First aid measures (what to do in case of accidents)

- Firefighting measures (suitable extinguishing media and protective measures)

- Measures in the event of a spill (handling of spills and leaks)

- Handling and storage (safe procedures and storage requirements)

- Exposure controls/protective equipment (limit values and protective equipment)

- Physical/chemical properties (appearance, smell, boiling point, etc.)

- Stability/reactivity (conditions that may cause hazardous reactions)

- Toxicology (effects on health)

- Ecology (impact on the environment)

- Disposal consideration (waste management)

- Transport (UN number and transport requirements)

- Regulations (laws and regulations that apply)

- Other information (additional info and update date)

Who is responsible?

The supplier’s responsibility

The supplier is responsible for preparing and supplying safety data sheets in Norwegian when a hazardous chemical is marketed in Norway. The SDS must be free, up-to-date and available to professional users. Among other things, the data sheet must contain Norwegian limit values and the Poisons Information Center’s emergency number. In the event of new information or regulatory changes, the supplier must update the SDS and send it to customers who have received the product in the last 12 months.

The employer’s responsibility

Procedures must be established to ensure that safety data sheets are of satisfactory quality, meet the requirements of the regulations and are updated when new information or versions become available. The employer is responsible for checking the SDS when new chemicals are used, ensuring that the data sheets are up to date, and obtaining missing information from the supplier if they are incomplete.

If an error is discovered, the employer must check whether a newer version is available and contact the supplier for an update. It is particularly important to ensure that special Norwegian requirements are taken care of in the SDS, for example that chapter 8 contains Norwegian administrative limit values, that chapter 15 refers to relevant Norwegian regulations, and that any Norwegian product registration number (PRN) is listed there.

Known challenges

Difficult to keep SDS up to date

Many companies find it challenging to keep their chemical inventory and SDS documentation up to date. When the company uses chemicals from several manufacturers and suppliers, it quickly becomes challenging to keep track of all the changes they make to their SDS.

There are no fixed deadlines for updating data sheets, and changes can therefore be made at any time. SDSs must be revised as soon as there is new information about hazards or regulations. This requires good routines to ensure that the SDS is always updated in relation to the chemicals the company actually uses.

Safety information must be easily accessible and understandable for employees

It is a legal requirement that employees have easy access to safety data sheets for the chemicals they work with. In practice, this can be challenging if the data sheets are stored in digital systems that employees have not been adequately trained in, behind passwords, or only exist in paper archives.

Most people who handle chemicals at work are not chemists, and it can be challenging for employers to provide ongoing and necessary training in how an SDS should be understood and used.

A good SDS provides an overview, creates security and ensures compliance with legal requirements. When companies take safety data sheets seriously, both HSE work and emergency preparedness are strengthened. So make sure you have a system that makes it easy to keep all safety data sheets up to date and available, so that safety information becomes a natural part of your daily work with chemicals.