What is an exposure register?

What is an exposure register?

Working with chemicals or in environments where such substances are present can pose health risks. Some chemicals do not cause acute symptoms, but can lead to long-term effects such as cancer, respiratory disease or reproductive damage many years after exposure. Here is an overview of what an exposure register is, and which companies it may be relevant for.

What is an exposure register?

An exposure register should document employees’ potential and actual exposure, including accidents, spills and other incidents that may have led to contact with hazardous substances. This may be in connection with hazardous substances or processes related to:

- Chemicals (carcinogenic, mutagenic and toxic to reproduction)

- Asbestos

- Mining work

- Biological material

- Radiation

There are only some chemicals that require registration in the exposure register. These are described in Chapter 31 of the Regulations on the performance of work.

Who can be exposed?

Several occupational groups that may be exposed to hazardous substances and processes.

Typical examples are:

- Employees in industry (chemical industry, metal production, welding and woodworking)

- Employees in construction (demolition, remediation, work with asbestos and concrete dust)

- Healthcare and laboratory workers (radiation, chemicals and infectious agents)

- Employees in renovation and waste management (biological material and hazardous waste)

- Employees in mines and tunnels (dust, gases and explosives residues)

- Employees within energy and research (radioactive material and ionising radiation)

Why do we need an exposure register?

In order to protect employees, the Working Environment Act and Chapter 31 of the Regulations on the Performance of Work require companies to keep an exposure register when working with carcinogenic, mutagenic or reprotoxic chemicals (CMR substances), as well as certain other hazardous exposures as described in the legislation. Because disease often develops many years after exposure, it is crucial to register such incidents immediately.

The register is an important tool for mapping work with high health risks in the workplace. It helps to:

- Follow up employees’ health over time

- Provide a basis for health checks and support for risk assessments

- Ensure documentation if illness occurs several years after exposure

What should an exposure register contain?

The content of the exposure register is clearly defined in the regulations. Based on the type of exposure (chemical, asbestos, rock work, biological or radiation), the content to be registered varies on the work subject to registration. The legislation is clear that the content of the register should not be anything other than what is described there.

Documentation and storage requirements

The register must be kept for a very long time, often between 40 and 60 years, depending on the type of exposure. The information must be available for as long as the employee is alive, and can be decisive in documenting occupational diseases and any compensation cases.

Individual employees have the right to access their own registrations. In addition, the register must be available to the Norwegian Labor Inspection Authority, occupational health services, safety representatives, the working environment committee and any other persons working with HSE in the company.

Who is responsible?

Both employer and employee have certain responsibilities, but it is the employer who has the main responsibility for creating and maintaining the exposure register.

Employee’s responsibility

- Follow the company’s routines and guidelines in connection with registration

- Report accidents, exposures or other situations that may have led to contact with hazardous substances

- Participate in necessary training and help ensure that the information recorded is correct

The employer’s responsibility

- Establish routines and guidelines for exposure registration

- Provide training on how employees should report

- Thoroughly document and retain records for a sufficient period of time

- Ensure that the register is used

- Ensure that employees have access to their own registrations

Known challenges

Inadequate reporting and follow-up

Many companies find that employees do not report exposures, either because the incident is perceived as minor, the routines are unclear, or because it is simply forgotten. This is often linked to a lack of training in chemical safety and understanding of the risk. In addition, many companies are unsure when they are actually required by law to keep an exposure register.

Difficulty storing registrations over a longer period of time

As some types of exposure require the register to be kept for up to 60 years, it requires good routines for both storage and for safeguarding privacy (GDPR). As long as the employee is alive, it should be possible to document any exposure, especially if there is a risk of cancer. As there are no specific requirements for how records are kept, many companies lack good enough routines to handle this.

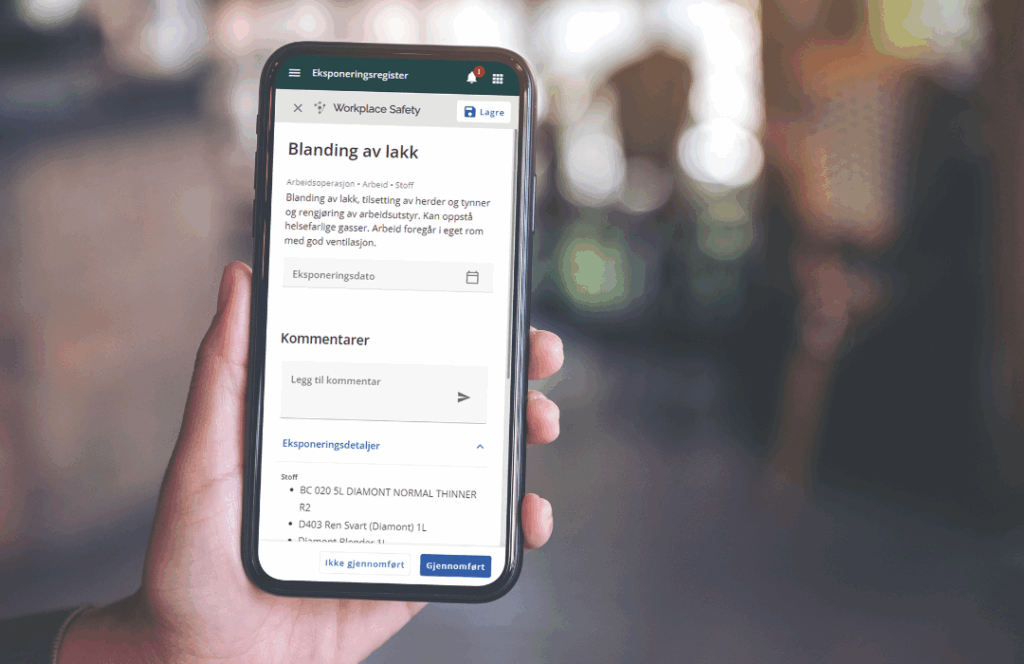

A well-maintained exposure register is an important tool for both the employee and the employer. It contributes to prevention, follow-up and documentation, especially because health damage often only becomes apparent many years after exposure. Digital HSE and chemical systems can help companies identify chemicals that are subject to registration, carry out the actual registration and ensure safe storage of the information.