Risk assessment of chemicals

This article was written for the Norwegian Automobile Industry Association and published in the member magazine Bilbransjen.

An important part of your HSE work

Risk assessment of chemicals is an important part of HSE work, especially in the automotive industry where employees handle a wide range of chemicals every day.

Chemicals can have hazardous properties, especially those used in workshops and paint shops. If handled incorrectly, they may cause acute or long-term health issues, environmental pollution, or even explosive incidents. Carrying out thorough risk assessments enables you to identify the necessary control measures to ensure safe use and management of chemicals.

Risk assessments must be documented in writing

In Norway, the requirements for chemical risk assessment are regulated by the Working Environment Act and regulations such as the Regulations on the Performance of Work. Employers are obligated to identify and assess all chemical substances used in the workplace, and every risk assessment must be documented in writing.

“The risk assessment should always cover the entire work operation in which the chemicals are used”

The way of use guides the risk assessment and measures

A risk assessment must always be based on the specific use of the chemical in question.

The assessment should evaluate the entire work operation in which the chemical is used. If the same chemical is applied in different work operations, this must either be reflected within a single risk assessment or addresses through separate assessments.

Different applications may require different protective equipment and additional training. For example, the use of diisocyanates with a high degree of exposure will trigger mandatory additional training.

Conducting a risk assessment

There are several ways to conduct a chemical risk assessment. This following steps provide a general overview of the process:

An updated chemical inventory: The chemical inventory provides an overview of all chemicals and their safety data sheets (SDS). Always use the latest version of the SDS and verify key information about hazardous properties.

Assessment of hazard: Assess the inherent hazards of the chemical using information from the SDS.

Exposure assessment: Analyse how the chemical is used, quantities handled, routes of exposure (e.g. inhalation, skin contact, and ingestion), frequency and duration of work, and existing workplace control measures.

Characterisation of risk: Combine hazard and exposure information to estimate the overall risk.

Implementation of control measures: Based on the risk assessment, implement measures to reduce risk, such as improved ventilation, appropriate PPE, or substitution with safer alternatives. Integrate these measures into work instructions, checklists, and training routines.

Documentation and auditing: Document the process and review it regularly to ensure assessments remain up to date.

Control measures

Control measures may include the following:

- Necessary ventilation

- Training of employees

- Use of protective equipment

For example, a risk assessment of car painting may include multiple chemicals. This may require isolation of the work area, local exhaust ventilation, training in the use of diisocyanates during spray application, establishing a designated processing zone, and use of protective equipment.

Work smart with user-friendly tools

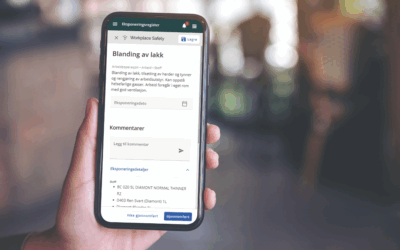

Digital chemical management systems provide structured processes that make it easier to conduct and document risk assessments in line with regulatory requirements.

Use the expertise of the occupational health service

The occupational health service is a key advisor in risk assessment and employee training on safe chemical handling.

With in-depth knowledge of safe working practices and chemical handling, they can help ensure a safe workplace.

Remember: if the risk conditions warrant it, it is a legal requirement to be affiliated with an approved occupational health service, so make full use of this resource.

Written by Hans Kristian Brekken, chemist and product developer at Workplace Safety.